The End of Earthquakes?

Published:

Introduction

Earthquakes not only cause numerous deaths but also significant economic losses due to the damage they inflict on various buildings. The 7.8 magnitude earthquake that struck Turkey in February 2023 resulted in more than 50,000 deaths and economic losses estimated at over 84 billion dollars. This devastating impact underscores the need to develop devices that mitigate damage to structures. Although devices designed to reduce such damage exist, the effects remain significant due to the unpredictability of earthquakes and because current structural systems are not adaptive but static. Therefore, a new approach is required for structural elements that can adapt in real-time to seismic conditions to prevent further damage. In light of this issue, magnetorheological (MR) isolators are proposed.

Magnetorheological (MR) isolators are devices designed to mitigate the effects of earthquakes on structures by using magnetoactive elastomers (MAEs). These intelligent materials combine a flexible polymer matrix with embedded magnetic particles, enabling an adaptive response under the influence of a magnetic field. The ability of MAEs to modify their mechanical properties in real-time makes them a structural element that can significantly reduce damage to any type of building, providing an innovative and effective solution for seismic protection.

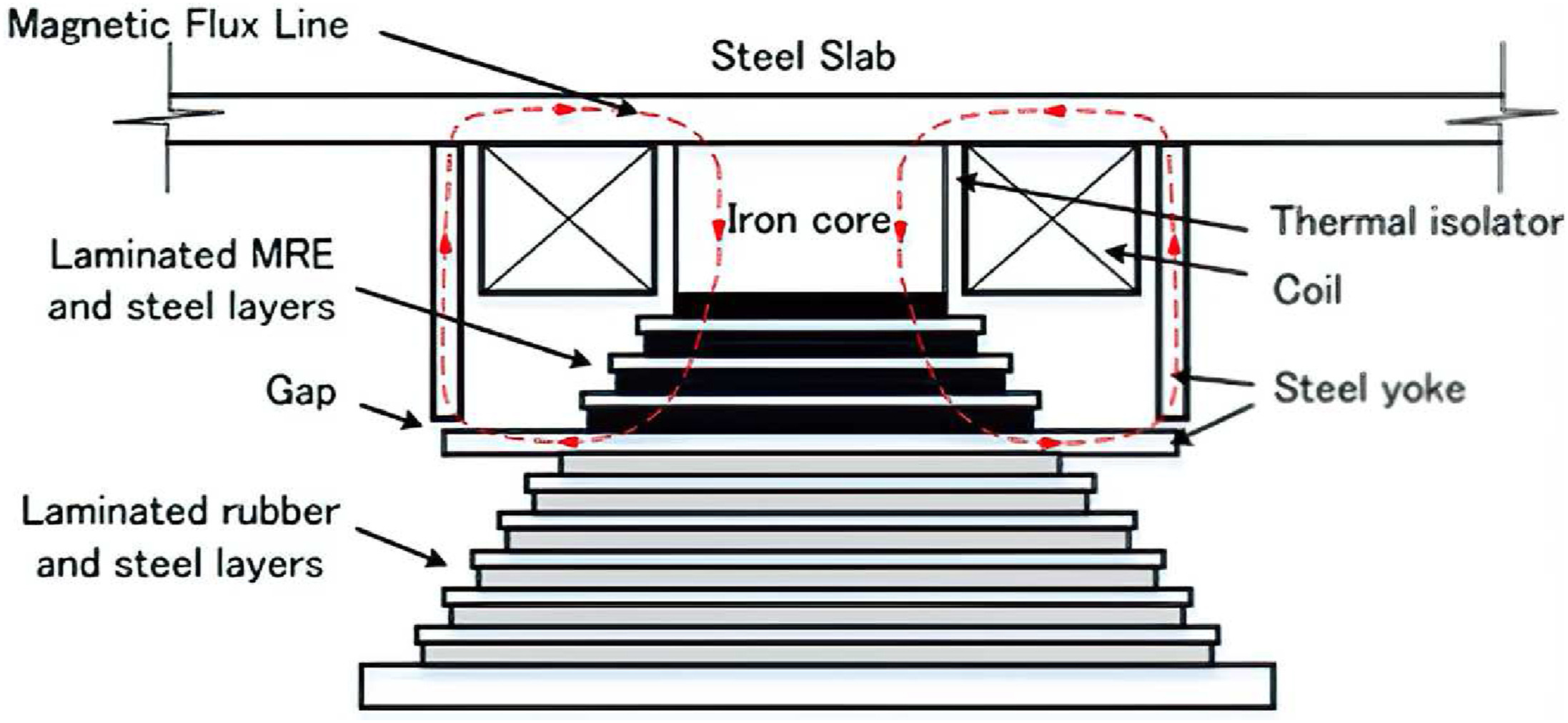

Fig.01: Schematic diagram and magnetic circuit of the conical MRE isolator.

How Magnetoactive Elastomers Work

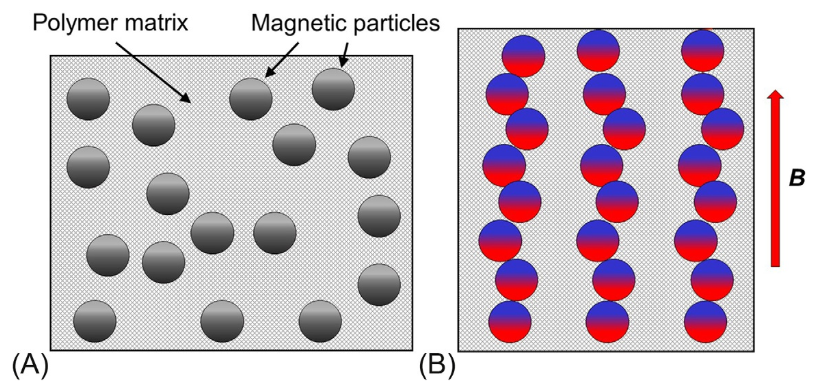

Magnetoactive elastomers (MAEs) are composite materials consisting of a highly flexible polymer matrix, such as polydimethylsiloxane (PDMS), in which magnetic particles, either ferromagnetic or ferrimagnetic, such as iron or magnetite particles, are dispersed. Under the influence of an external magnetic field, these particles become magnetized, generating forces and torques that induce changes in their orientation and position within the polymer matrix. This process, known as magnetization, results in material deformation due to magnetic interactions.

Fig. 2: Schematic representation of (A) a MAE with an isotropic distribution of magnetic filler particles in a polymer matrix in a zero magnetic field and (B) structuring of magnetic filler particles into a homogeneous shape in a magnetic field.

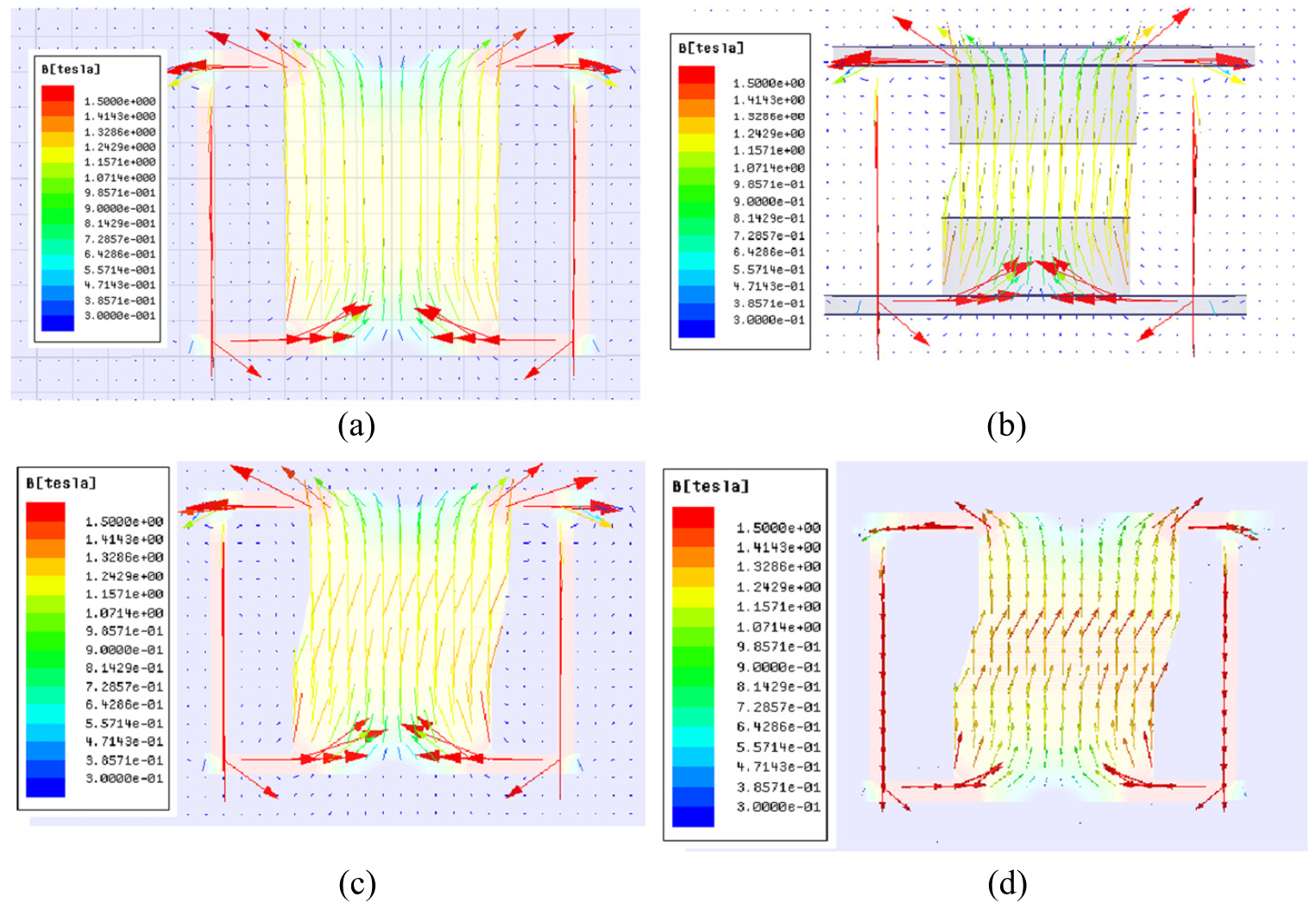

The behavior of MAEs is based on the relationship between the shear modulus of the polymer matrix (G) and the saturation magnetization (Ms) of the magnetic particles. The equation describing this interaction is κ = μ0Ms^2/G, where μ0 is the permeability of free space. A high κ value indicates a high responsiveness of the MAE to the magnetic field, allowing precise adjustments in its mechanical properties and controlled deformation.

Fig. 3: Magnetic flux line and magnitude in a MRE base isolator; (a) without deformation, (b) 5 mm deformation, (c) 10 mm deformation, and (d) 15 mm deformation.

Applications of MAEs in Seismic Isolators

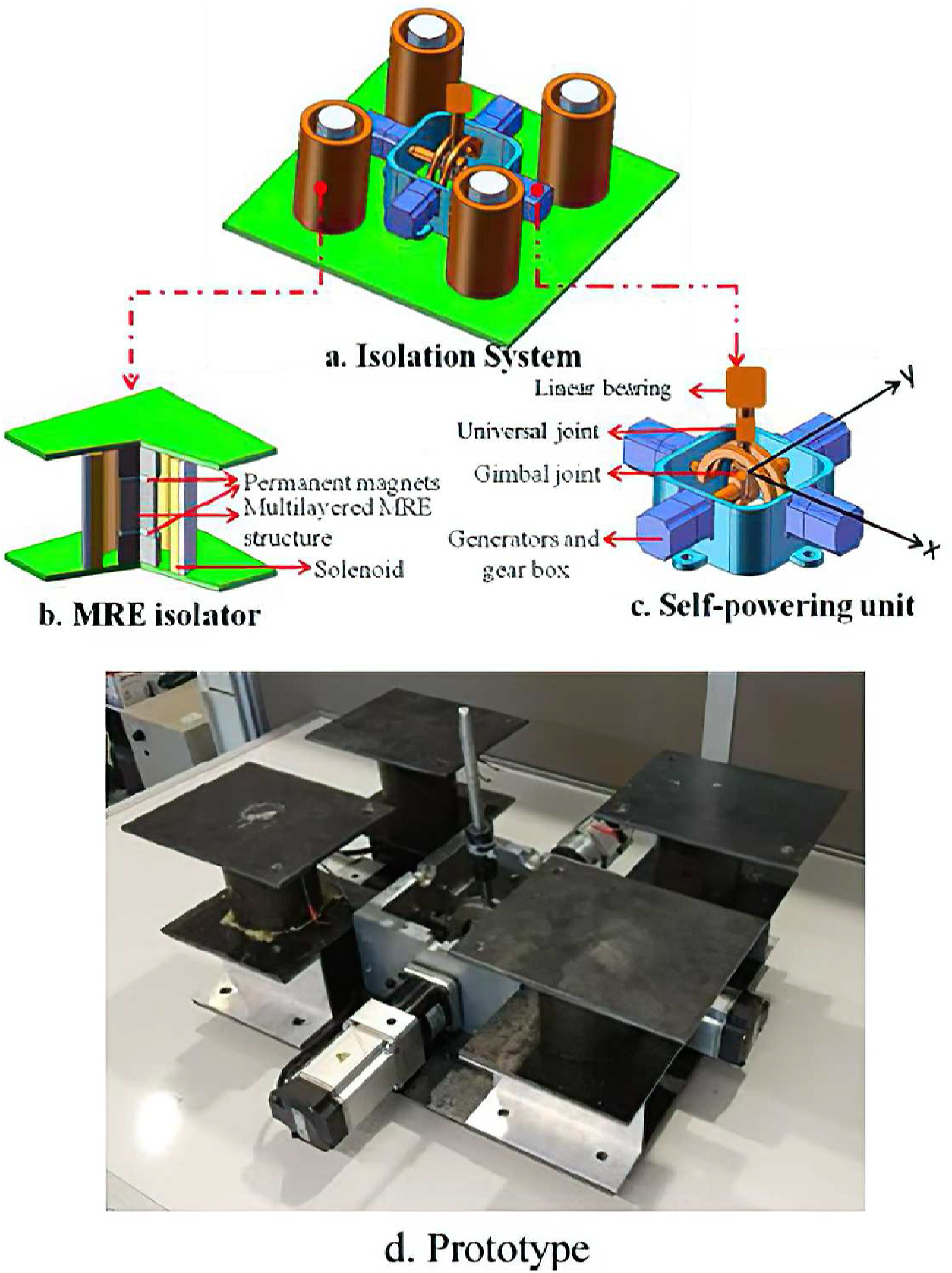

In seismic isolation systems, magnetoactive elastomers (MAEs) are used to develop devices that can dynamically adjust their stiffness and damping capacity in response to vibrations induced by an earthquake. These devices are designed to adapt to seismic conditions in real-time by applying an externally controlled magnetic field. During a seismic event, a control system monitors vibrations and adjusts the magnetic field to optimize energy absorption and reduce forces transmitted to the structure.

MAEs act as solid analogs to magnetorheological (MR) fluids, where the magnetic particles are dispersed in an elastomeric matrix rather than a carrier fluid. This configuration allows MAE-based isolators to maintain a solid and stable structure while adjusting their mechanical properties under a magnetic field. Additionally, the ability of MAEs to respond quickly to changes in the magnetic field makes them ideal for applications where adaptability and immediate response are crucial.

Fig. 4: Structure and prototype of the self-powered MRE isolation system.

Challenges of Using Magnetorheological Isolators

- Real-Time Control: Implementing real-time control requires developing systems capable of continuously monitoring seismic vibrations and adjusting the magnetic field immediately. This necessitates high-speed hardware and software to process and react to seismic data almost instantaneously.

- Development of AI Algorithms: It is crucial to develop advanced AI algorithms that can predict seismic response and adjust the magnetic field accordingly. These algorithms must be capable of learning and adapting to different seismic movement patterns to optimize the MR isolator’s response.

- System Robustness and Reliability: Control systems must be extremely robust and reliable, capable of operating under extreme conditions without failure. This is essential to ensure the safety and effectiveness of seismic isolation during high-intensity seismic events.

- Integration of High-Precision Sensors: Integrating high-precision sensors and fast communication systems is essential to ensure a coordinated and effective response from the isolation system. These sensors must provide accurate and real-time data on seismic conditions and the MR isolator’s performance.

- Energy Consumption and Maintenance: Magnetic field control requires energy, which can increase the energy consumption of buildings equipped with MR isolators. Additionally, regular maintenance is needed to ensure the system functions correctly, potentially increasing operational costs.

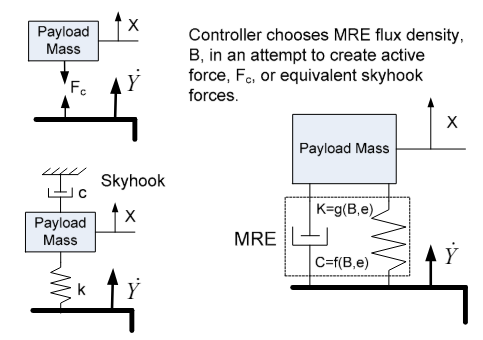

Fig. 5: Controller methodology. The stiffness of the MRE depends on the deformation, e, and the flux density, B.

Conclusion

Magnetorheological (MR) isolators represent a significant innovation in the field of civil engineering, providing a technologically advanced application designed to prevent both loss of human life and substantial economic losses. These devices offer a highly adaptable and effective solution for the protection of structures against earthquakes. The uniqueness of MR isolators lies in their ability to adjust their mechanical properties in real-time through the application of a controlled magnetic field. This allows for effective mitigation of seismic vibrations, significantly improving structural safety and minimizing damage during earthquakes.

However, the successful implementation of this technology critically depends on the integration of advanced artificial intelligence (AI) systems that allow precise and real-time control of the magnetic field. The continuous development and refinement of these systems are essential to maximizing the effectiveness of MR isolators. As these technologies evolve, magnetorheological isolators have the potential to revolutionize the design and protection of infrastructure against seismic events, marking a significant milestone in how these threats are addressed in civil engineering.

Bibliography

- Böse, H., Rabindranath, R., & Ehrlich, J. (2012). Soft magnetorheological elastomers as new actuators for valves. Journal of Intelligent Material Systems and Structures, 23(9), 989-994.

- Cha, Y. J., Zhang, J., Agrawal, A. K., Dong, B., Friedman, A., Dyke, S. J., & Ricles, J. (2013). Comparative studies of semiactive control strategies for MR dampers: pure simulation and real-time hybrid tests. Journal of Structural Engineering, 139(7), 1237-1248.

- Jin, S., Yang, J., Sun, S., Deng, L., Chen, Z., Gong, L., … & Li, W. (2023). Magnetorheological elastomer base isolation in civil engineering: a review. Journal of Infrastructure Intelligence and Resilience, 100039.

- Kashima, S., Miyasaka, F., & Hirata, K. (2012). Novel soft actuator using magnetorheological elastomer. IEEE Transactions on magnetics, 48(4), 1649-1652.

- Li, Y., Li, J., Li, W., & Du, H. (2014). A state-of-the-art review on magnetorheological elastomer devices. Smart materials and structures, 23(12), 123001.

- Opie, S., & Yim, W. (2009, July). Design and control of a real-time variable stiffness vibration isolator. In 2009 IEEE/ASME international conference on advanced intelligent mechatronics (pp. 380-385). IEEE.

- Shamonin, M., & Kramarenko, E. Y. (2018). Highly responsive magnetoactive elastomers. In Novel Magnetic Nanostructures (pp. 221-245). Elsevier.

- Yoshioka, H., Ramallo, J. C., & Spencer Jr, B. F. (2002). “Smart” base isolation strategies employing magnetorheological dampers. Journal of engineering mechanics, 128(5), 540-551.