Introduction

Throughout history, construction materials have evolved significantly, adapting to the needs for durability, strength, and efficiency of each era. From the early civilizations using natural materials like stone and clay, to contemporary advancements in composite materials and nanotechnology, the quest to improve infrastructure has been constant. In ancient times, the earliest stone structures, such as the pyramids of Egypt and the temples of Mesopotamia, demonstrated advanced construction techniques for their time. With the advent of the Roman Empire, concrete was introduced—a mixture of lime, water, and volcanic stone—which enabled the construction of more complex and durable structures, such as the Pantheon and Roman aqueducts.

During the Middle Ages and the Renaissance, construction materials continued to improve with the use of more sophisticated bricks and mortars. However, it was during the Industrial Revolution that significant advancements were made with the introduction of steel and reinforced concrete, allowing for the construction of taller buildings and longer bridges. In the 20th century, the development of new materials such as prestressed concrete and advanced metal alloys revolutionized civil engineering. However, despite these advancements, issues related to the durability and maintenance of concrete structures persisted. The need for new materials that could offer solutions to these problems led to the research and development of self-healing concretes.

Self-healing concretes are designed to autonomously repair cracks and minor damages without human intervention. These materials can be classified into several types based on the self-healing mechanism employed.

Types of Self-Healing Concrete

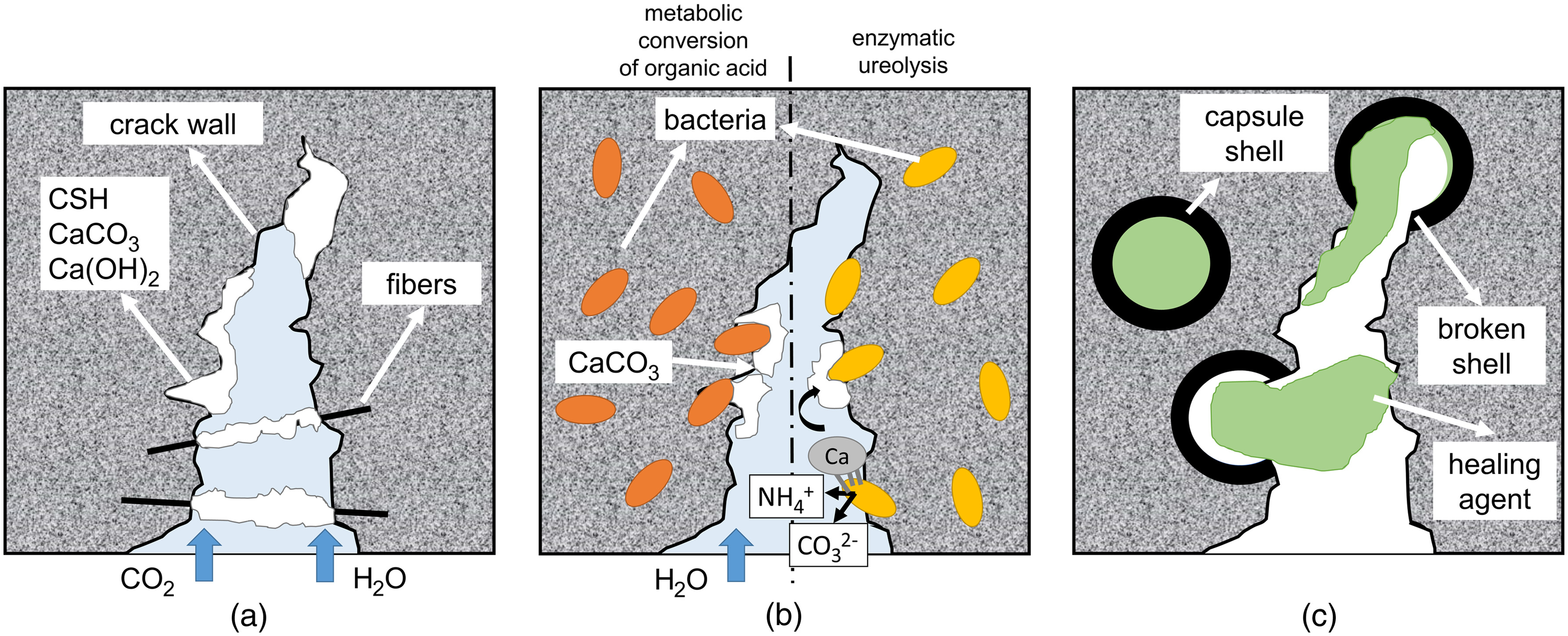

Chemical Agent-Based Self-Healing Concrete: This type of concrete incorporates microcapsules filled with chemical compounds within the concrete matrix. When a crack occurs, the capsules break and release their contents, which react with the environment, typically water, to form products that seal the cracks. The resulting chemical reactions, such as the formation of silica gels or the hydrolysis of silicates, help fill and repair the cracks, restoring the material’s integrity.

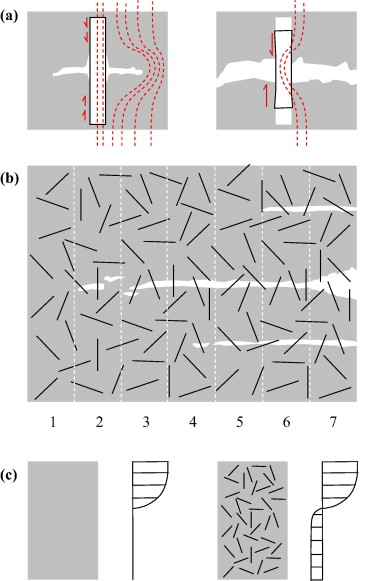

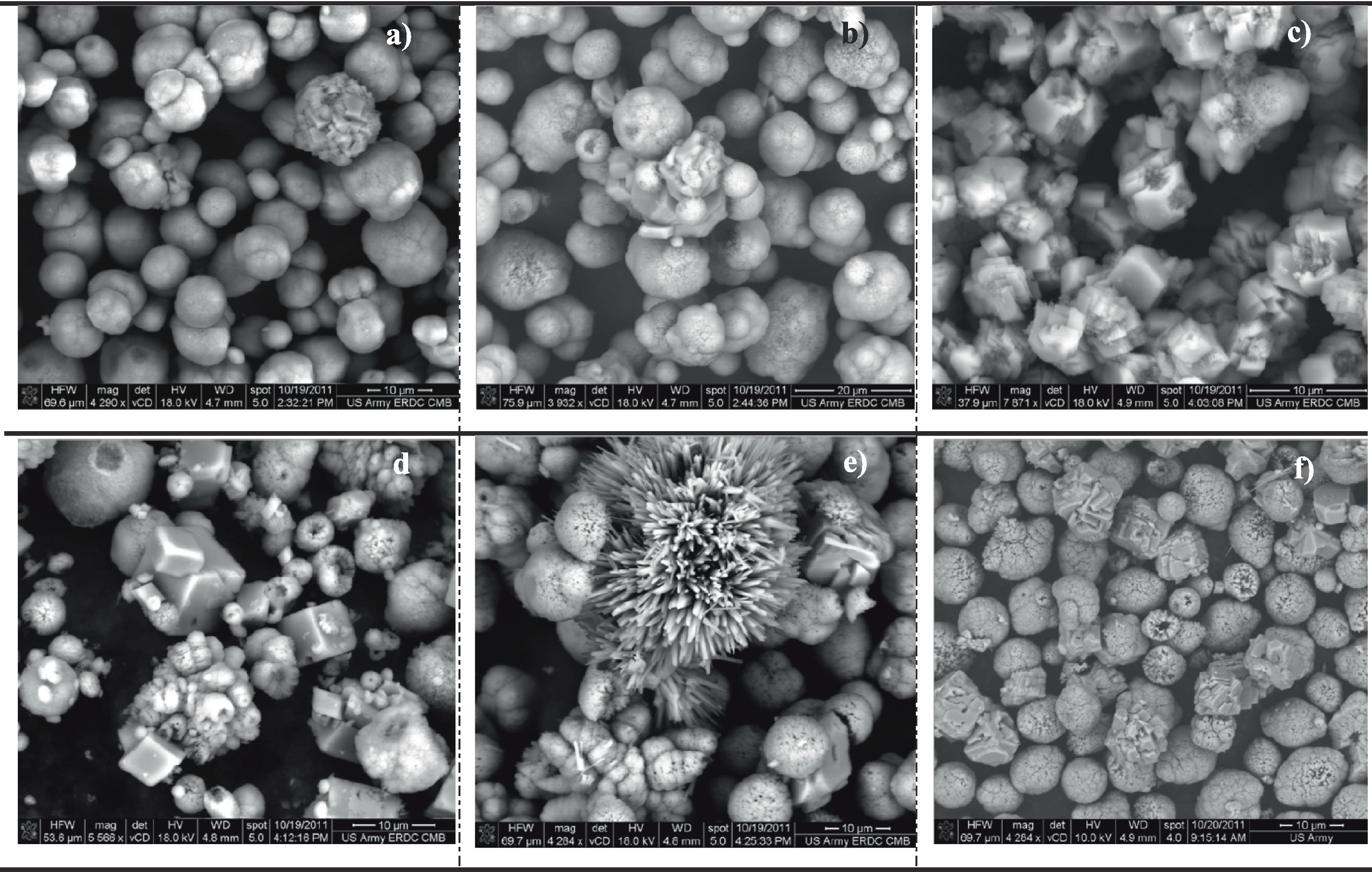

Microfiber-Reinforced Concrete: Microfiber-reinforced concrete contains fibers uniformly distributed throughout the mix. These fibers can stitch the cracks, limiting their propagation and allowing the natural chemical reactions of the concrete, such as carbonation, to repair the cracks. The microfibers enhance tensile strength and control crack width, providing continuous and autogenous repair. This type of concrete not only increases the material’s durability but also improves its load-bearing capacity and resistance to cracking.

Fig. 1. Description of Load Transfer Through a Fiber (a), Formation of Multiple Cracks (b), and Ideal Representation of Stresses in the Material (c). Source: "Snoeck, D. et al 2015".

- Polymer-Based Self-Healing Concrete: Polymer-based self-healing concrete incorporates microcapsules containing polymers that, when cracked, release a healing agent that seals the cracks and restores the material’s integrity. These polymeric agents can be adhesives or resins that solidify rapidly upon contact with air or water, providing a quick and effective solution for cracks. Applications include the use of polyurethanes and epoxies, known for their durability and adhesive properties.

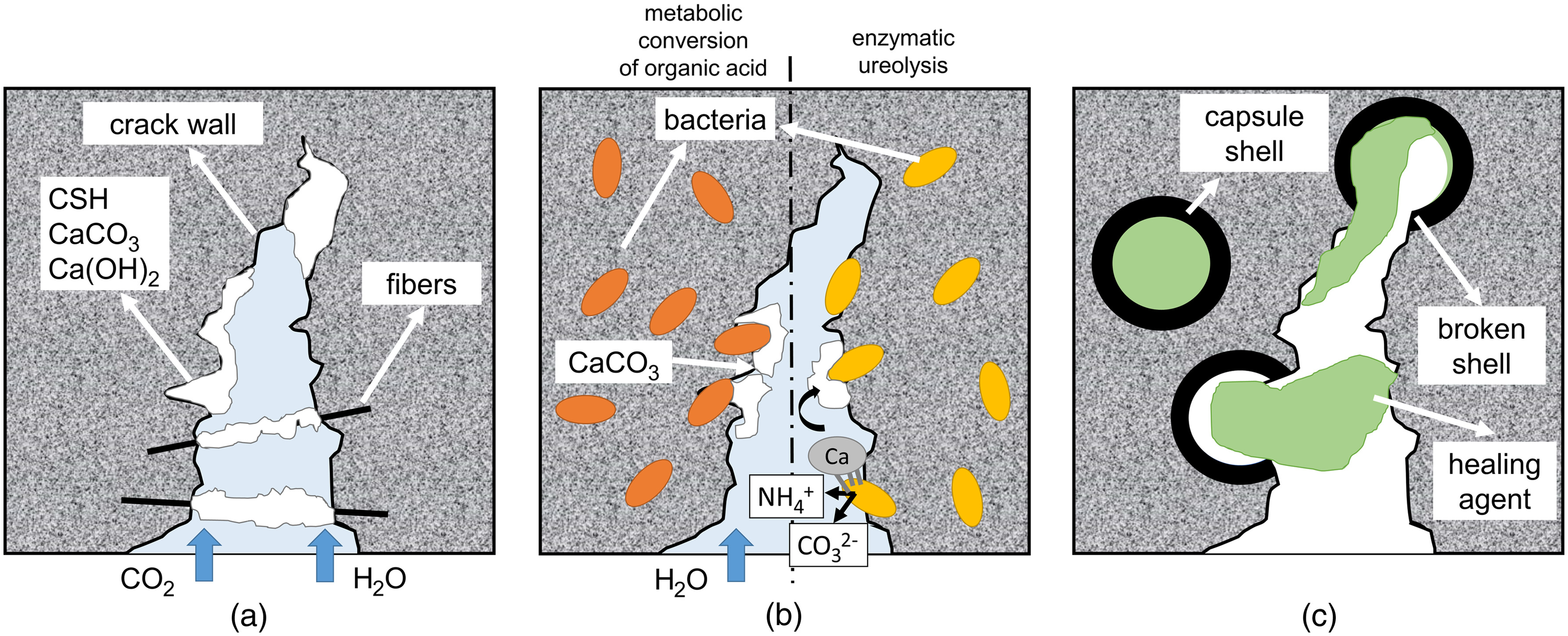

Fig. 2. Self-Healing Mechanisms: (a) Autogenous; (b) Autonomous Bacteria-Based; and (c) Autonomous Capsule-Based. Source: "Rajczakowska, M. et al 2019".

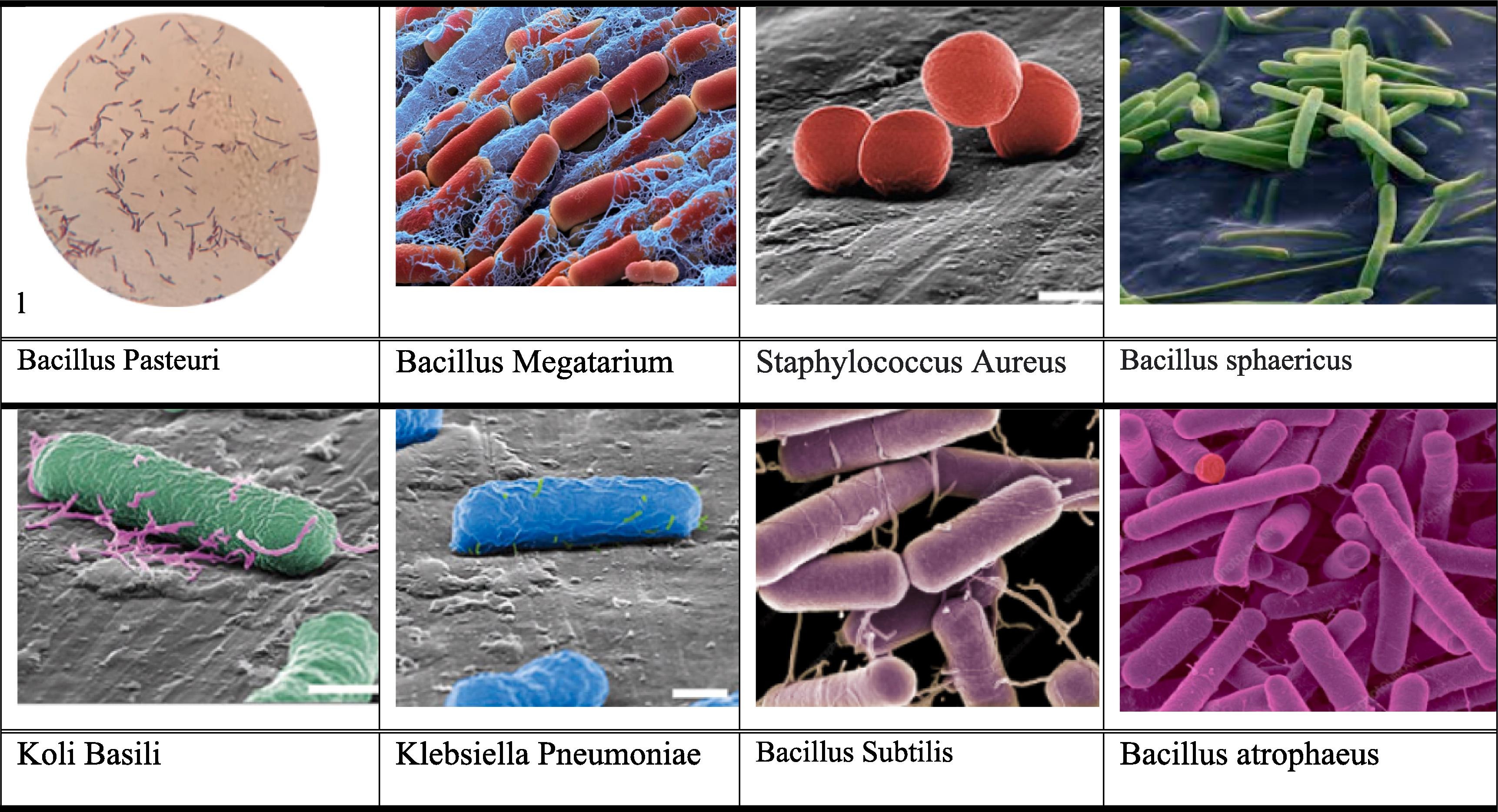

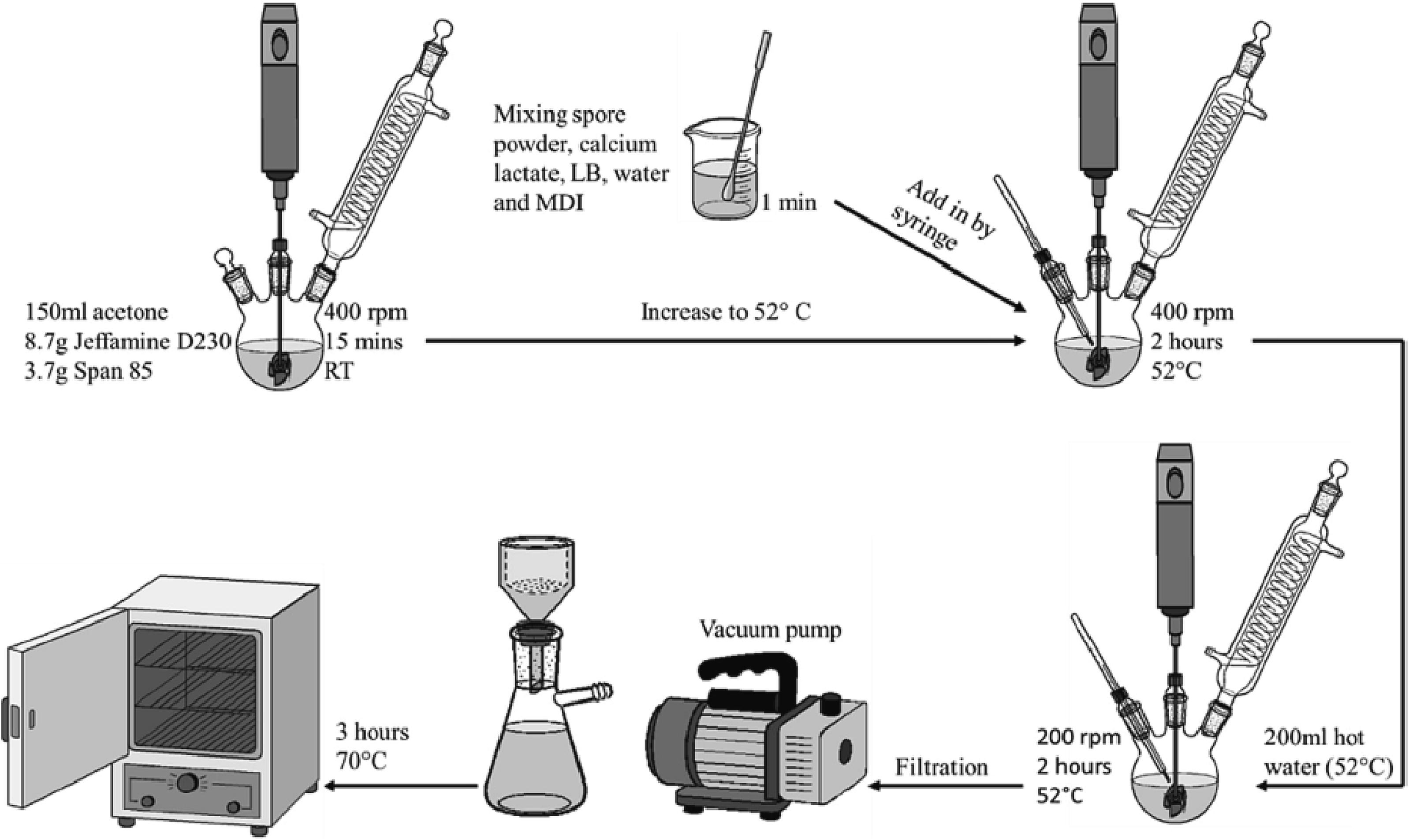

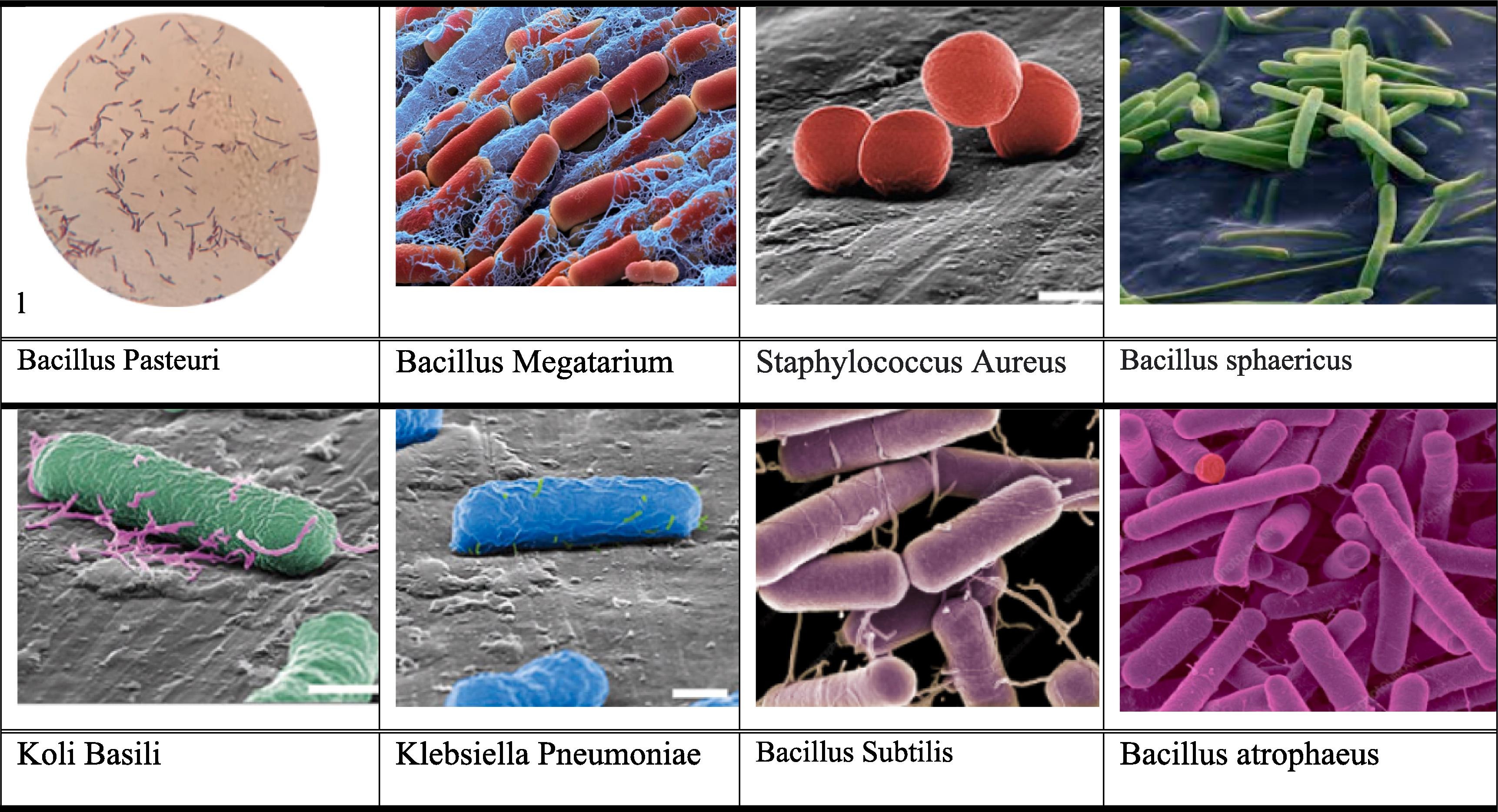

- Bacteria-Based Self-Healing Concrete: This type of concrete uses bacteria that, when activated in the presence of water, produce calcium carbonate that biologically seals the cracks. The most commonly used bacteria belong to the Bacillus genus, selected for their ability to survive in extreme conditions and their effectiveness in precipitating calcium carbonate. Species such as Bacillus pasteurii, Bacillus sphaericus, and Bacillus cohnii are popular due to their high efficiency in alkaline environments like concrete.

Fig. 3. SEM Images of Different Types of Bacteria. Source: "Aytekin, B. et al 2023".

In this article, we will delve deeper into bacteria-based self-healing concrete, demonstrating how biotechnology can be integrated with construction to create innovative solutions. These materials represent a significant advancement in civil engineering, combining microbiology with construction technology to enhance the durability and sustainability of infrastructure.

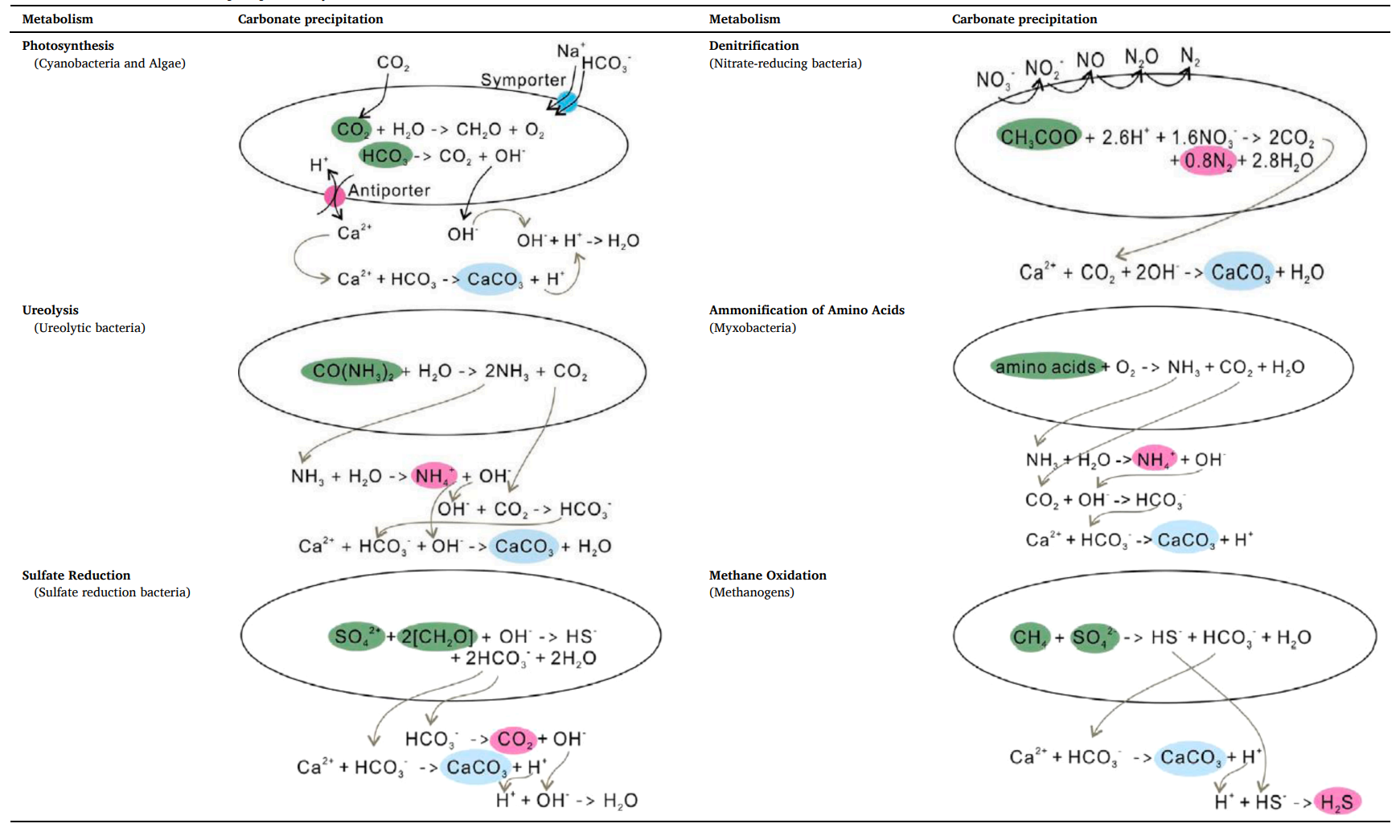

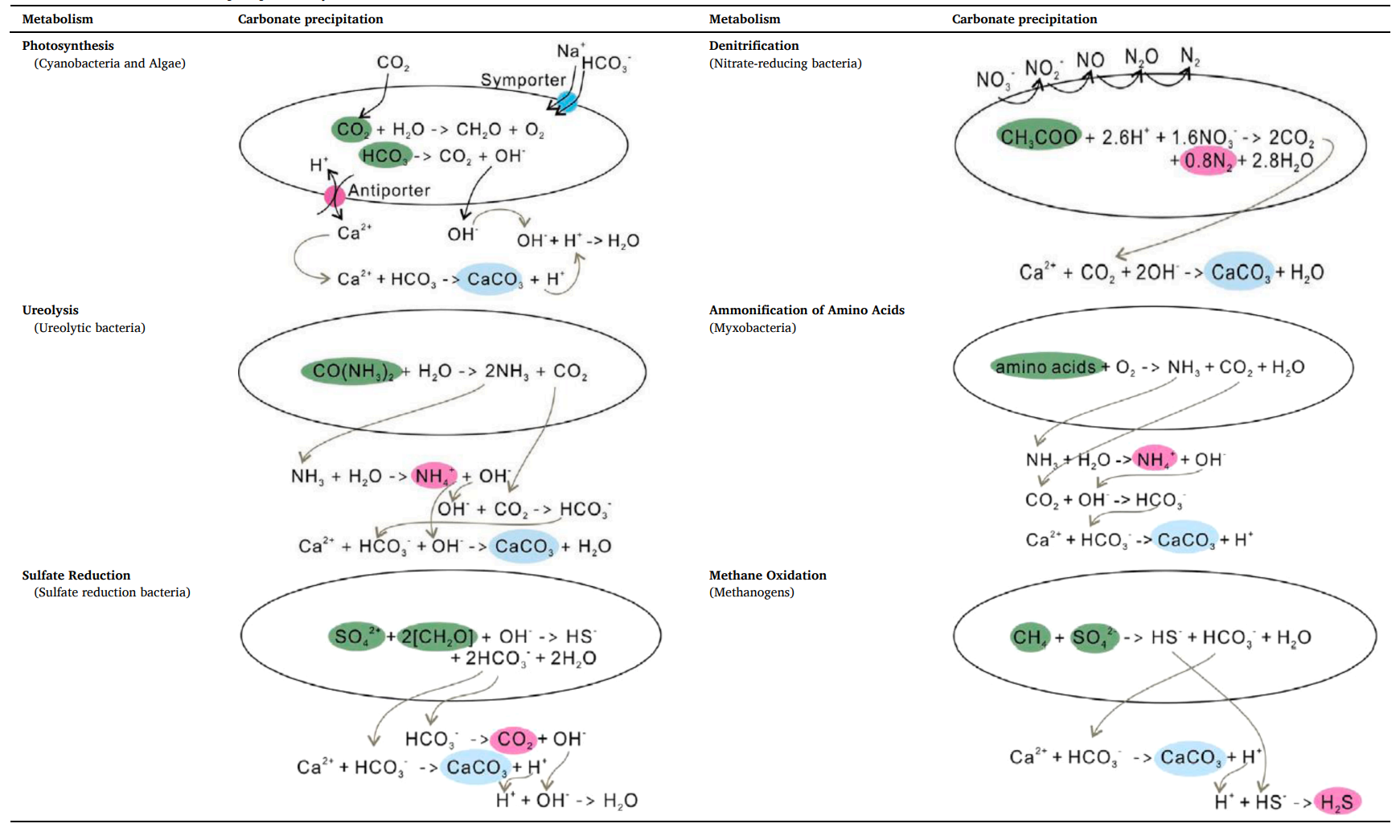

Biomineralization Process

The biomineralization process involves the formation of inorganic crystals through biological activities. In this context, the precipitation of calcium carbonate (CaCO3) is the key mechanism. Bacteria such as *Bacillus pasteurii*, used in concrete, trigger biomineralization primarily through urea hydrolysis, where the enzyme urease hydrolyzes urea into ammonia and carbon dioxide. This reaction raises the local pH, facilitating the precipitation of CaCO3 in the presence of calcium ions. This increase in pH, crucial for the formation of calcium carbonate, occurs when ammonia is converted into ammonium, releasing hydroxides that increase the alkalinity of the bacteria's immediate surroundings. As supersaturation conditions are reached, calcium and carbonate ions combine to form CaCO3, which deposits on the surfaces of cracks, sealing them and restoring the concrete's structural integrity.

Fig. 4. Metabolism of Calcium Carbonate Precipitation by Bacteria. Source: "Aytekin, B. et al 2023".

Environmental Variables in Bacteria-Based Self-Healing Concrete

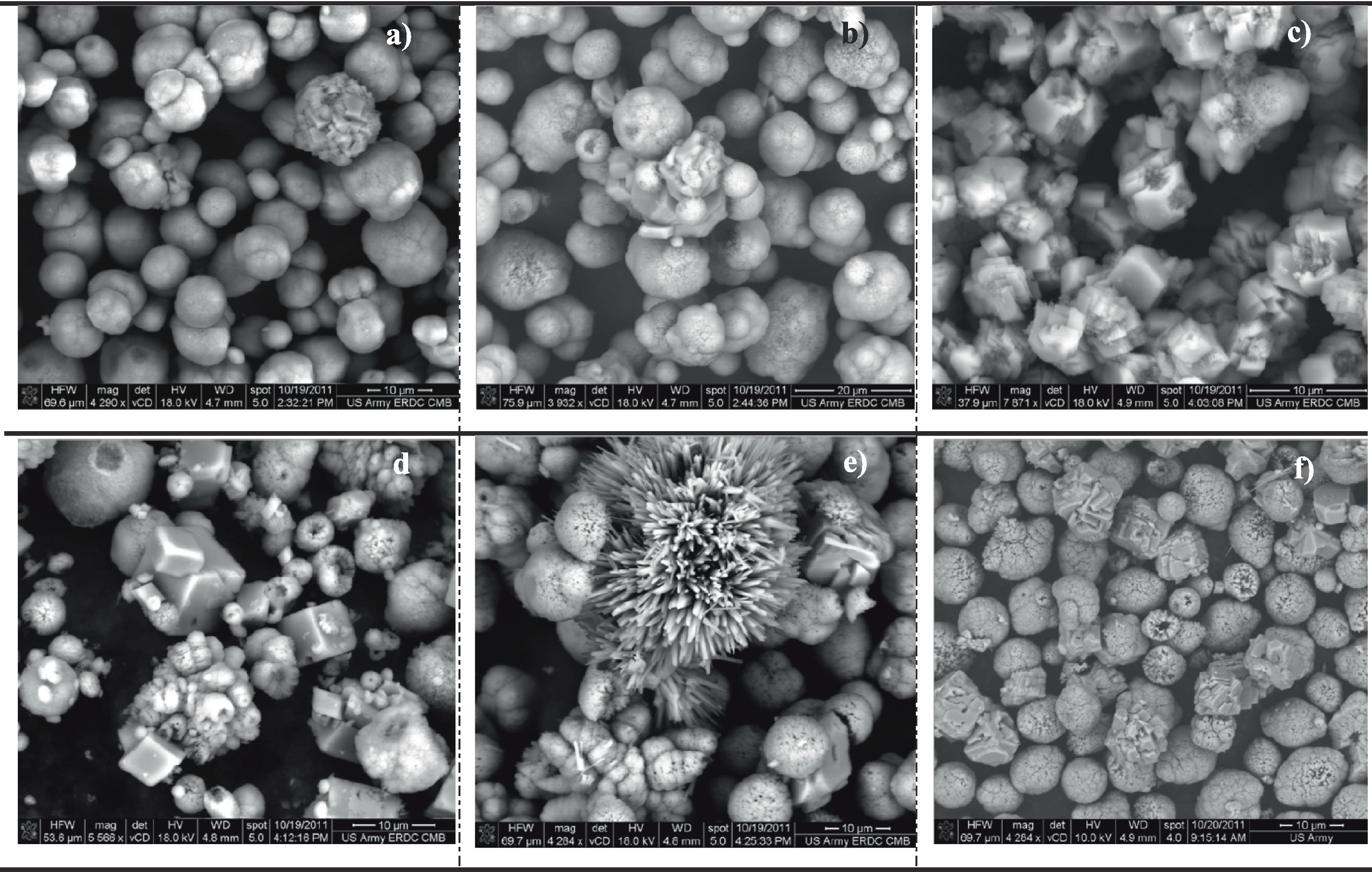

The efficiency of microbial self-healing in concrete is significantly influenced by several environmental factors, particularly temperature, pH, and nutrient availability. Optimal temperature conditions are crucial, as most ureolytic bacteria, such as *Bacillus pasteurii*, exhibit optimal urease activity at temperatures between 25°C and 45°C, with the highest efficiency typically around 30°C. At this temperature, chemical and enzymatic reactions progress more rapidly, increasing the rate of CaCO3 precipitation. Conversely, temperatures that are too high or too low can inhibit bacterial activity and urease function, reducing the concrete's self-healing capacity.

Fig. 5. SEM Images of Calcium Carbonate Crystals Precipitated at Different Temperatures. Source: "Aytekin, B. et al 2023".

The pH of the environment also plays a critical role in microbial activity and the biomineralization process. Urease, the enzyme responsible for hydrolyzing urea into ammonia and carbon dioxide, functions most effectively at a pH of around 8.0. High pH levels facilitate ammonia production, which in turn increases the local pH, promoting calcium carbonate precipitation. However, extremely high or low pH levels can negatively affect bacterial growth and enzyme stability, thereby hindering the self-healing process. It is essential to maintain a pH that supports both the metabolic activities of the bacteria and the stability of the urease enzyme.

Nutrient availability is another vital factor that affects the viability and activity of bacteria in self-healing concrete. A balanced nutrient medium that includes calcium sources, such as calcium lactate or calcium chloride, is essential for bacterial metabolic processes and the subsequent formation of CaCO3. The type of calcium source used can influence the morphology and efficiency of the precipitated calcium carbonate, and different sources can lead to variations in crystal size and structure. Ensuring an adequate supply of nutrients helps maintain bacterial activity and promotes continuous crack healing over time.

Implementation and Encapsulation Strategies

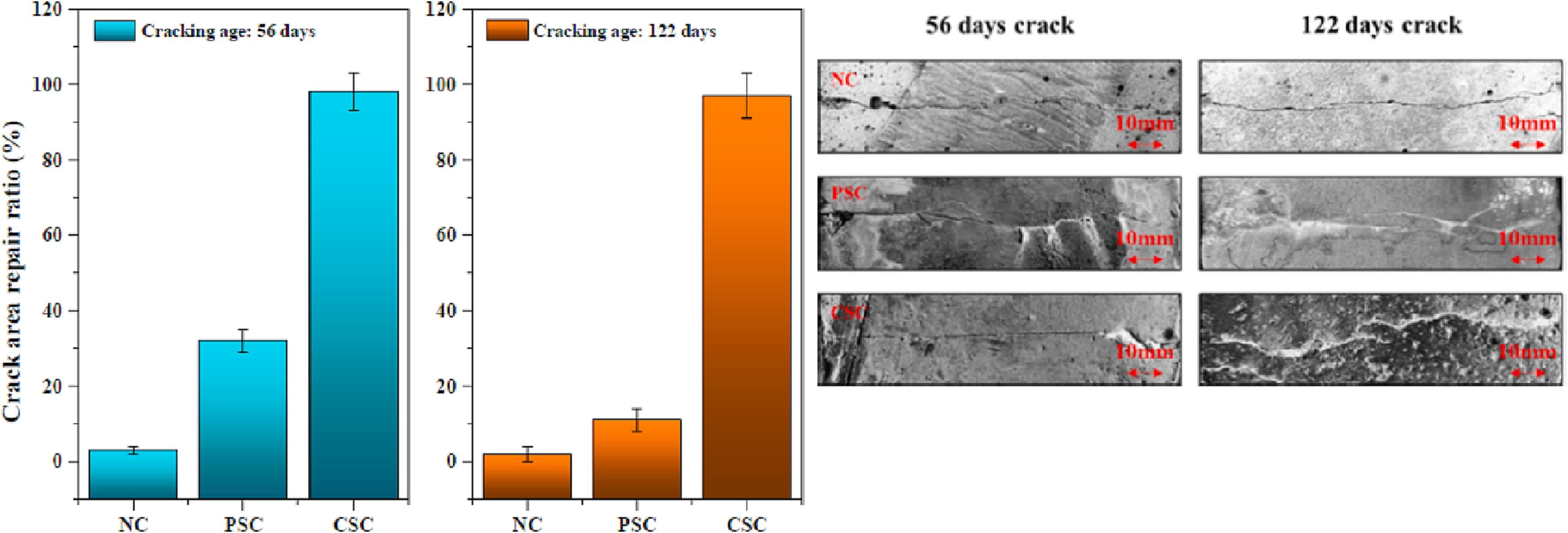

The implementation of bacteria-based self-healing concrete involves various strategies that ensure the viability and effectiveness of microorganisms in the alkaline environment of concrete. One primary strategy is the direct addition of bacteria to the concrete mix. However, this method can expose the bacteria to adverse conditions, such as high alkalinity and mechanical stresses during mixing, which may reduce their viability and repair capacity. To mitigate these challenges, encapsulation techniques have been developed to protect the bacteria and keep them viable until they are activated to repair cracks.

Encapsulation involves the use of various carrier materials, such as hydrogels, microcapsules, and lightweight aggregates. Hydrogels act as water reservoirs, providing the necessary moist environment for bacterial activity and calcium carbonate (CaCO3) precipitation. Microcapsules, made of materials like polymers or glass, contain bacteria and nutrients that are released when the microcapsules break due to crack formation in the concrete. This controlled release ensures that the bacteria are only activated in the presence of water and oxygen, initiating the repair process. Another technique is the impregnation of bacteria into lightweight aggregates, where porous aggregates are soaked in a bacterial solution and then mixed with the concrete. This method protects the bacteria during mixing and provides a gradual release of microorganisms and nutrients over time. Additionally, the use of oxygen and nutrient release tablets has been explored, which, when dissolved in the presence of moisture, release the necessary components for bacterial activity, facilitating CaCO3 precipitation and crack healing. Each of these implementation and encapsulation strategies is designed to maximize the efficiency of the self-repair process, ensuring that the bacteria can survive in the hostile concrete environment and be effectively activated to repair cracks, improve durability, and prolong the life of concrete structures.

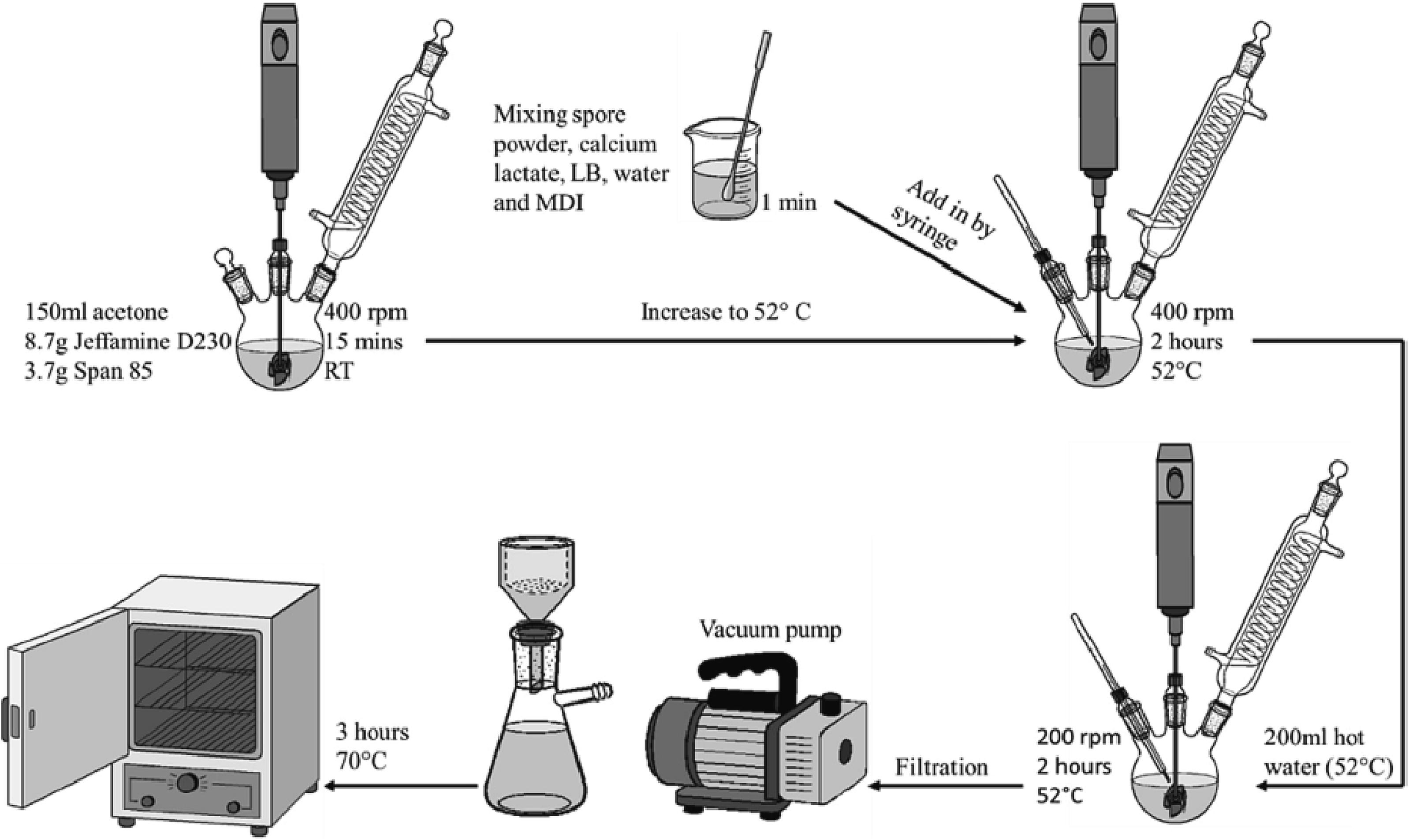

Fig. 6. Illustration of the synthesis and encapsulation of bacteria in a polyurea capsule. Source: "Aytekin, B. et al 2023".

Mechanical Properties

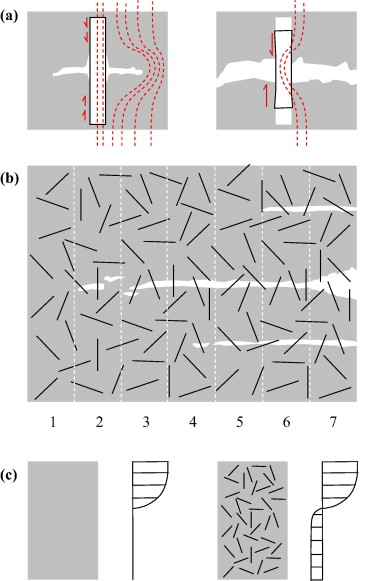

The use of bacteria-based self-healing concrete has shown significant improvements in the mechanical properties of the material, particularly in terms of crack sealing and increased compressive strength. The precipitation of calcium carbonate (CaCO3) induced by bacterial activity within cracks not only seals them but also restores the structural integrity of the concrete by filling voids and reducing porosity. Studies have shown that concrete with bacteria can heal cracks up to 0.8 mm wide, significantly larger than those healed by autogenous processes. Additionally, the inclusion of bacteria can increase compressive strength by up to 30%, depending on bacterial concentration and environmental conditions. This increase in strength is primarily attributed to the conversion of weak Ca(OH)2 into solid CaCO3, which plays a strong structural role, and the ability of bacteria to act as nucleation sites for the formation of calcium silicate hydrate (C-S-H) gel during cement hydration, thus accelerating the cement hydration process.

On the other hand, bacterial cell walls can directly act as nucleation sites for concrete hydration due to their carried negative charges. However, some researchers suggest that the CaCO3 precipitation from microbially induced calcium carbonate precipitation (MICCP) reactions could be soft and powdery instead of forming hard crystals, which might negatively affect compressive strength in certain circumstances. Furthermore, bacterial activity reduces water permeability and chloride infiltration, thereby protecting reinforcement steel against corrosion and extending the service life of concrete. Although it has been observed that higher bacterial concentrations lead to greater calcite precipitation, the optimal concentration to maximize compressive strength does not necessarily coincide with the highest bacterial concentration, as an excess of bacteria could clog surface pores and affect cement hydration.

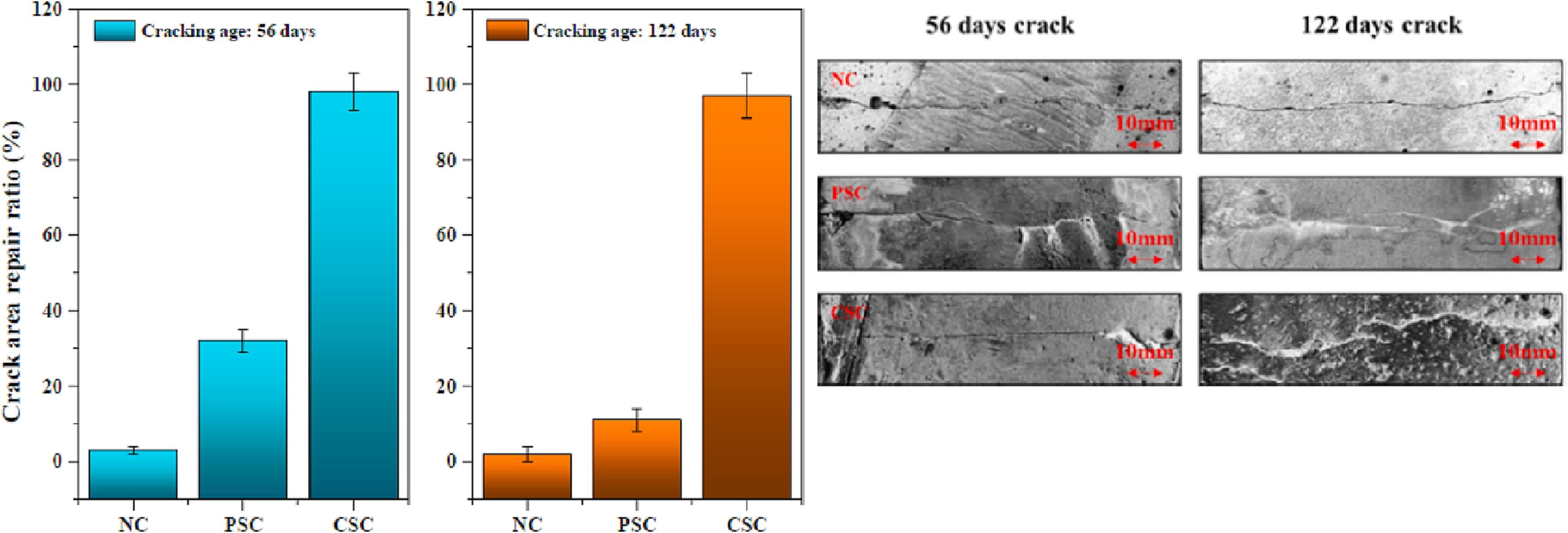

Fig. 7. Comparison of the repair rate at the crack mouth (NC: normal concrete, PSC: bacterial self-healing concrete with powder-based healing agents; CSC: bacterial self-healing concrete with capsule-based healing agents). Source: "Aytekin, B. et al 2023".

Conclusion

Bacteria-based self-healing concrete represents a promising advancement in construction materials, offering substantial benefits and addressing critical challenges in the durability and maintenance of concrete. This innovative material autonomously heals microcracks, reducing the need for manual inspection and repair, which in turn prolongs the lifespan of structures and reduces maintenance costs. The self-healing process involves bacteria precipitating calcium carbonate to seal cracks and enhance the overall durability of concrete by reducing water permeability and protecting reinforcement steel from corrosion.

The sustainability of this technology is noteworthy, as it reduces the frequency and extent of repairs, thus conserving materials and energy. The inclusion of bacteria also improves mechanical properties, such as compressive strength, with reported increases of up to 30%. Additionally, the use of natural processes for self-healing aligns with green construction practices by reducing reliance on synthetic chemical additives.

However, integrating bacteria into concrete involves complexities such as careful encapsulation, nutrient supply, and maintaining optimal environmental conditions, which can increase initial costs and production complexity. The viability of bacteria in the alkaline environment of concrete and their performance under varying conditions are significant challenges that need to be addressed. Long-term studies are essential to evaluate the durability and effectiveness of this technology over extended periods.

Future research should aim to optimize bacterial strains, nutrient media, and encapsulation methods to improve the efficiency and cost-effectiveness of self-healing concrete. Long-term performance studies in real-world conditions will provide valuable insights into its practicality and durability.

In conclusion, bacteria-based self-healing concrete offers a sustainable and efficient solution to concrete cracking, with significant potential to improve the durability and longevity of concrete structures. While challenges remain, ongoing research and technological advances have the potential to overcome these obstacles, paving the way for broader adoption and implementation in the construction industry.

Bibliography

- Amran, M., Onaizi, A. M., Fediuk, R., Vatin, N. I., Muhammad Rashid, R. S., Abdelgader, H., & Ozbakkaloglu, T. (2022). Self-healing concrete as a prospective construction material: a review. Materials, 15(9), 3214.

- Ansari, N., & Joshi, R. (2019). A study on self-healing property of concrete using E. coli as bacteria. International Journal of Research and Analytical Reviews, 6(2), 61-66.

- Aytekin, B., Mardani, A., & Yazıcı, Ş. (2023). State-of-art review of bacteria-based self-healing concrete: Biomineralization process, crack healing, and mechanical properties. Construction and Building Materials, 378, 131198.

- Bindschedler, S., Cailleau, G., & Verrecchia, E. (2016). Role of fungi in the biomineralization of calcite. Minerals, 6(2), 41.

- Chen, X., Yuan, J., & Alazhari, M. (2019). Effect of microbiological growth components for bacteria-based self-healing on the properties of cement mortar. Materials, 12(8), 1303.

- Davies, R., Teall, O., Pilegis, M., Kanellopoulos, A., Sharma, T., Jefferson, A., … & Lark, R. (2018). Large scale application of self-healing concrete: Design, construction, and testing. Frontiers in Materials, 5, 51.

- Hungria, R., Hassan, M. M., Arce, G., Mousa, M., King, G., Milla, J., & Rupnow, T. (2023). Optimizing the self-healing efficiency of hydrogel-encapsulated bacteria in concrete. Journal of Materials in Civil Engineering, 35(4), 04023048.

- Perito, B., & Mastromei, G. (2011). Molecular basis of bacterial calcium carbonate precipitation. Molecular Biomineralization: Aquatic Organisms Forming Extraordinary Materials, 113-139.

- Qureshi, T., & Al-Tabbaa, A. (2020). Self-healing concrete and cementitious materials. Advanced Functional Materials, 32, 137-144.

- Rajczakowska, M., Habermehl-Cwirzen, K., Hedlund, H., & Cwirzen, A. (2019). Autogenous self-healing: a better solution for concrete. Journal of Materials in Civil Engineering, 31(9), 03119001.

- Seifan, M., Samani, A. K., & Berenjian, A. (2016). Bioconcrete: next generation of self-healing concrete. Applied Microbiology and Biotechnology, 100, 2591-2602.

- Snoeck, D., & De Belie, N. (2015). From straw in bricks to modern use of microfibers in cementitious composites for improved autogenous healing–A review. Construction and Building Materials, 95, 774-Here is the content in Markdown format with centered images and captions: